Metalworking

Practical Action

Blacksmithing

Forging or blacksmithing is one of the oldest methods of making objects from metal. An

outline of blacksmithing is described in the Practical Action Technical Brief Blacksmithing.

The main item required is a forge where the metal can be heated. The other basic

requirements are an anvil, a hammer, and some tools to hold the metal while it is being

worked.

An example of the type of product produced is described in the Practical Action Technical

Brief The Donkey Plough.

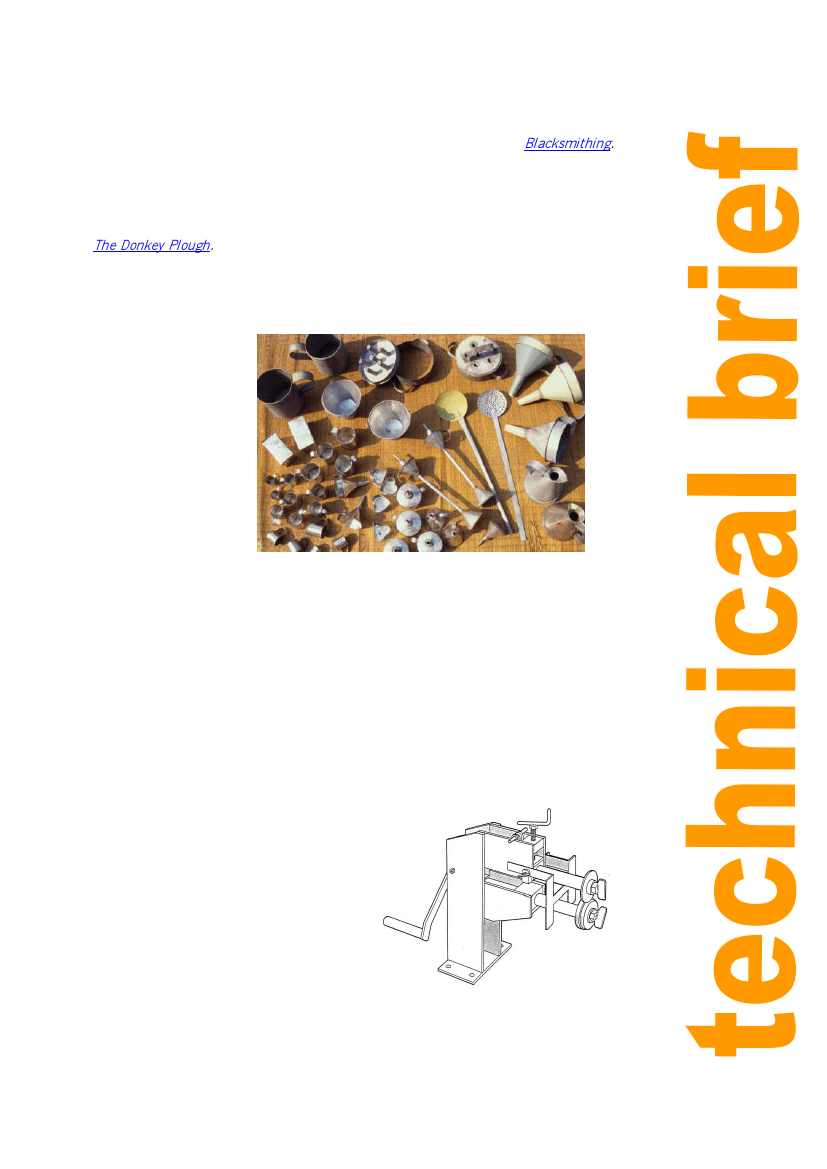

Tinsmithing / Sheet metalwork

Sheet metal work is the process of producing such objects as buckets, boxes, tanks, drums,

cupboards, desks, ducting, vehicle bodies, etc, from sheet metal. Traditionally tin was

commonly used which gave

its name to the process but

now steel is often used. In

developing countries scrap

car bodies are a common

source of material.

Tinplate, used for making

articles such as funnels,

where economy of material

combined with ease of

working are required, is

usually in the thickness

range of 0.3 to 0.8 mm.

Thickness of galvanized

steel in common use range

from about 0.7 to 2.5 mm.

Aluminium, copper, brass

and uncoated steel sheet are

used in thicknesses from

0.3 to 3 mm.

Figure 2: Examples of the some of the tin products

produced by the trainers who carry out training in

tinsmithing by Practical Action Bangladesh. Photo

credit: Practical Action/Zul

Metal folding and bending

The simplest approach to use a hammer and anvil to produce the shapes you want. Various

designs of low cost folding and bending equipment have been developed by Apt Design &

Development based on practical experience.

Folding machines work on a variety of

principles. For general purposes, such as

folding sheet metal to make a box, a box-and-

pan type machine is convenient. This consists

of a flat table, a clamp to hold down the sheet,

and an edge that folds up or down to force over

the projecting edge of the sheet. Various

configurations are used to allow the bending of

intricate shapes such as internally flanged

boxes. Another form of bending machine, an

angle bender, works by forcing the sheet into a

V notch by the action of a blade applied by

hand lever or by power. These machines are less

versatile but once set up for a particular job,

can be quicker in use than a folding machine.

Figure 3: A Jenny for sheet metal work.

Designed by Graham Saunders.

Illustration by Graham Sounders

2